Electronic potting glue

Product Name:

Electronic potting glueModel No.:

YZ-9800A/YZ-9800BPrice:

时价Minimum Order:

202

Product Abstract:

YZ - 9800 silicone flame retardant potting glue, is designed for electronics, electrical components and electrical components designed potting a two-component molding liquid silicone rubber. YZ - 9800 product before curing, has the good liquidity, using the operating time is moderate, when using (such as two components according to the proportion of mixed) easy to operate, after curing in 60 ~ + 2500 c temperature range can be use for a long time, has a small shrinkage rate, good resistance to high and low temperature (60 ℃ ~ 200 ℃), flame retardancy, thermal conductivity, good sealing, high temperature when using good resistance to sulfide to return the original and good dielectric properties, etc. For filling materials such as plastic, glass, ceramic potting use without pretreatment. Two components, in accordance with the A: B = 1:1 (weight ratio), blending with products with room temperature and middle temperature curing two ways to choose from, no corrosive to metal and non-metallic materials, allowable operating time is moderate, but deep inside and outside at the same time curing.

- Product Description

A brief introduction.

YZ - 9800 silicone flame retardant potting glue, is designed for electronics, electrical components and electrical components designed potting a two-component molding liquid silicone rubber. YZ - 9800 product before curing, has the good liquidity, using the operating time is moderate, when using (such as two components according to the proportion of mixed) easy to operate, after curing in 60 ~ + 2500 c temperature range can be use for a long time, has a small shrinkage rate, good resistance to high and low temperature (60 ℃ ~ 200 ℃), flame retardancy, thermal conductivity, good sealing, high temperature when using good resistance to sulfide to return the original and good dielectric properties, etc. For filling materials such as plastic, glass, ceramic potting use without pretreatment. Two components, in accordance with the A: B = 1:1 (weight ratio), blending with products with room temperature and middle temperature curing two ways to choose from, no corrosive to metal and non-metallic materials, allowable operating time is moderate, but deep inside and outside at the same time curing.

2. Use

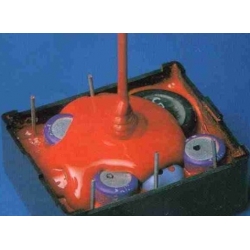

Suitable for flame retardant and heat dissipation requirements of the electronic components of the potting. Such as all kinds of communication module, tiny perfusion encapsulation of transformer, high power LED drive power supply, high temperature resistance, thermal conductivity, insulation, sealing, waterproof, by environmental pollution, eliminate stress and prevent vibration, achieve the purpose of long-term reliable protection of sensitive circuits and components.

3. Typical technical indicators:

The serial number

project

The technical requirements

(thermal conductive flame retardant silicone molding)

Before the curing

1

appearance

9800 a

White flowing liquid

9800 b,

Film of flowing liquid

2

Viscosity of cp

9800 a

5800-5800.

9800 b,

4800-4800.

3

Mixing ratio (weight)

A 100-100

4

Curing conditions

25 ℃

1.5 3 h (can be adjusted)

5

Heat up

60 ℃

30 min (can be adjusted)

After curing

6

appearance

Film of the elastic solids

7

G/cm3 density

1.30 to 1.50

8

Shaw hardness HA

43-48

9

Tensile strength mpa

1.82

10

Elongation at failure %

80-80.

11

Dielectric loss MHz. %

0.3

12

The volume resistance

5.0 x 1014

13

The relative dielectric constant MHz

2.8

14

Breakdown strength KV/mm

18

15

Coefficient of thermal conductivity of W/m * k

0.8

16

Flame retardant UL94; level

V - 0

4. Use the method and the matters needing attention

1, when used, will be A component and B components in proportion according to good, in A clean container fully mixing, "bubbles in the vacuum potting. By potting components surface should be clean.

2, impact YZ - 9800 - a/B may contain silicone flame retardant potting of thermal conductivity of rubber curing or require adhesion good components materials, must be used to form a complete set of special bottom coating agent.

3, for automatically filling and sealing line, can be A component and B components respectively clean vacuum bubble (defoaming time about 10 min - 20 min), with metering pump will play to A component and B components in proportion to the static mixer, mixing potting.

4, when using this product allows the operation time and environmental temperature, the higher the temperature, shorter operation time is allowed.

5, this product is easy to be molecules containing P (P), S (sulfur), N (nitrogen) elements "poison" and influence the curing effect of organic compounds, pay attention to when using clean, prevent the impurities mixed with.

6, the product of avoid by all means and condensation of water or add curing agent type silicone rubber, add hardener of epoxy resin, polyurethane, mixed or contact.

5. Packaging, storage and transportation

1, this article points A, B two components, packaging respectively in 5 kg/barrel, white barrel of 20 kg/drum, or according to user requirements specified packaging through consultation.

2, this product during storage and transportation, shall be kept in a cool, dry place, prevent from. Storage period of 12 months, are the reinspection, if accord with a standard, still can use.

3, this product according to non-dangerous goods storage and transportation.

6. Safety and environmental protection

This series product is not dangerous chemicals, can according to non-dangerous goods storage and transportation, use, no poison and pollution on the human body and environment, so, do not need to take more precautions.

- Related Products

- LED display potting glue

- High power LED potting glue

- Flame retardant electronic potting glue

- Electronic potting glue

- Transparent electronic potting glue

- Condensation type electronic potting glue

- Room temperature vulcanization molding electronic potting glue

- Liquid tank filter seal jelly glue

- The LED driver power supply pouring sealant

- Silicone potting glue of thermal conductivity

- [Return Home] [Print] [Go Back]

Products Search

Brand Zone

Contact Us

Contact Person:

Xiaohai QiTel:

+8613533634945Fax:

Renewable resources, reasonablyE-mail:

158354113@qq.com-