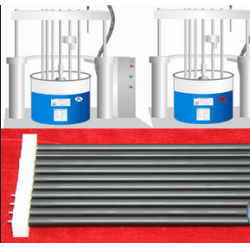

The developer roller (DR) with liquid conductive adhesive

Product Name:

The developer roller (DR) with liquid conductive adhesiveModel No.:

LIM6969-45A/BPrice:

时价Minimum Order:

20

Product Abstract:

This product is a two-component platinum catalytic liquid silicon rubber, suitable for injection molding process. The main use For laser printers, photocopiers and other office equipment on the roller surface elastic material.

- Product Description

Basic models: LIM6969-45 a/B, LIM6969 - a/B, 50 LIM6969-65 - a/B,

The product description

This product is a two-component platinum catalytic liquid silicon rubber, suitable for injection molding process. The main use

For laser printers, photocopiers and other office equipment on the roller surface elastic material.

The main features

High resilience, low volatile, high temperature resistant, low compression permanent deformation rate

Under the environment of 20 ℃, A/B component mixture after sealing condition of safe operating time is 5 days, shorten at higher temperatures safe operating time.

The main application

Printer and copier enhancement roller roller surface elastic material

packaging

20 kg/barrel or 200 kg/barrel

Typical physical properties table

- Related Products

- Add molding glue

- Since the viscose

- With liquid silica gel

- The nasal bracket with silicone rubber

- Breast pad with silicon gel insoles

- The silicone injection molding the human body

- Breast implants with silica gel

- Cars with silicone

- Automobile airbag surface coating of silicone rubber

- Ignition wire silicone

- [Return Home] [Print] [Go Back]

Products Search

Brand Zone

Contact Us

Contact Person:

Xiaohai QiTel:

+8613533634945Fax:

Renewable resources, reasonablyE-mail:

158354113@qq.com-